What Is a Shuttle-Type Intensive Warehouse?

A shuttle-type intensive warehouse system is a semi-automated or fully automated shuttle warehouse that uses autonomous, battery-powered shuttles to move pallets within deep lane racking structures. This system dramatically increases storage density compared to traditional methods like Selective or Drive-In racking. It is the ideal solution for FIFO (First-In, First-Out) or LIFO (Last-In, First-Out) inventory management in high-volume, medium-SKU operations, utilizing advanced pallet shuttle automation.

Key Features & Advantages

Our shuttle systems are modular, scalable, and engineered for high throughput warehousing:

High Storage Density

Achieves superior cubic utilization by minimizing aisle space and maximizing storage depth, delivering the best high-density warehouse storage systems for bulk goods.

High Space Utilization (Up to 80%)

The system enables high space utilization by eliminating the need for lift truck maneuvering within the racks, maximizing every square foot of your floor plan.

Fast Shuttle Retrieval

Robotic shuttles operate at high speeds, providing a rapid warehouse shuttle retrieval system that significantly boosts the speed of placing and retrieving goods.

Multi-directional Shuttle Operation

Advanced systems use a multi-directional shuttle warehouse design, often incorporating a central lift or shuttle mother-child vehicle to move the shuttle between different rack levels and aisles, increasing system flexibility and performance.

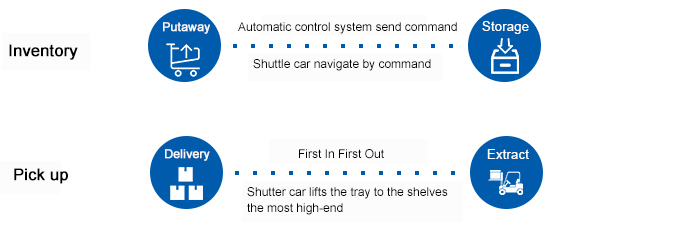

How Shuttle Intensive Systems Work

In a typical setup, a pallet is placed on the rack's entry point by a forklift or conveyor. The automated pallet shuttle system then takes the pallet and drives it into the racking channel, automatically placing it in the next available position. For retrieval, the shuttle reverses the process, bringing the pallet back to the aisle entrance for pickup, ensuring precise and autonomous pallet shuttle automation.

Applications of Shuttle-Type Warehouses

The shuttle-type intensive storage system is best suited for:

- High-Volume Inventory: Storing a high quantity of relatively few SKUs (e.g., beverages, packaged goods, bulk consumables).

- Buffer Storage: Creating a high-throughput buffer between manufacturing and shipping.

- Cold Storage: Automating operations in deep-freeze facilities where human access is limited.

- Batch Picking: Efficient staging and retrieval of pallets required for consolidated outbound shipments.

Shuttle System Options & Integration

We build full-scale automated shuttle warehouse ecosystems by integrating complementary technologies:

Automated Stereoscopic Warehouse

The shuttle system can be the dense storage core of a larger, multi-level automated stereoscopic warehouse structure.

Robotic Mini-Load System

Integration allows seamless management of both small items (Mini-Load) and bulk pallets (Shuttle) within the same facility.

Picking System

The system can feed full pallets to an integrated depalletizing and automated picking system for piece-picking operations.

Pallet Stacking Systems

Connects the output of the warehouse shuttle system directly to downstream processes like robotic palletizers.

AGVs

AGV Automatic Guided Vehicle systems can be used to transport pallets from the shuttle input/output stations to other areas of the warehouse.

AS/RS Integration

Shuttle systems can be integrated with AS/RS System controls to provide alternative storage and retrieval methods within the same facility footprint.