What Is an AS/RS System?

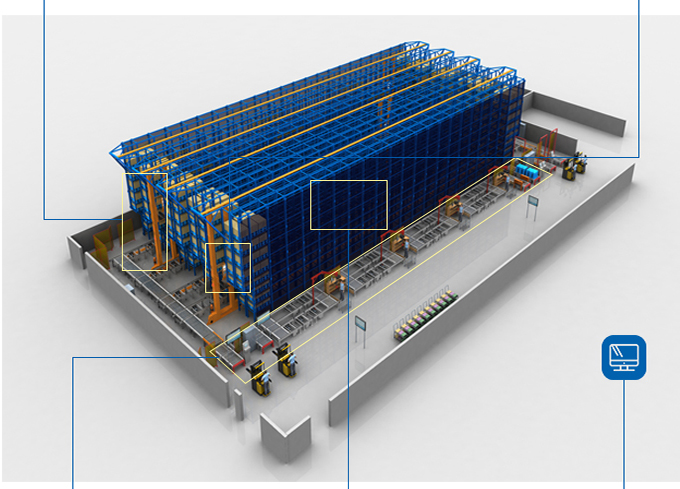

An automated storage and retrieval system (AS/RS) is a core component of modern automated warehouse storage. It replaces manual handling with computer-controlled machinery—like stacker cranes and robotic shuttles—to deposit and retrieve loads. By operating in narrow, tall structures (high bay automated storage system), AS/RS maximizes cubic space utilization and enables fully automated, Goods-to-Person fulfillment, drastically improving inventory accuracy and labor efficiency.

AS/RS Features and Advantages

Implementing an ASRS warehouse system delivers dramatic improvements across key operational metrics:

- Maximized Density: Achieves the highest possible storage density by building vertically (high bay warehousing system) and minimizing aisle space.

- Speed and Throughput: Provides exceptionally fast retrieval speeds, critical for high-volume order fulfillment.

- Accuracy: Inventory tracking is nearly 100% accurate, eliminating mispicks and lost product.

- Safety: Removes personnel from the racking environment, creating a safer operation.

- Reduced Labor Costs: Automates the repetitive task of moving inventory, focusing labor on value-added tasks.

- Integration: Seamlessly connects to conveyors (ASRS conveyor integration) and other downstream processes like packing and shipping.

Types of AS/RS Systems

We design and integrate specialized AS/RS solutions based on your inventory profile (size, weight, and velocity).

Unit Load AS/RS

Designed for large, heavy unit loads, typically full pallets. This system uses massive ASRS stacker crane system or sophisticated vehicles for automated pallet storage and retrieval in tall, deep lanes. This is the ultimate solution for high density retrieval system of bulk goods.

Mini Load AS/RS

Tailored for small, lightweight inventory stored in totes, trays, or cartons. Mini load ASRS is characterized by high-speed shuttles or extractors that provide rapid, accurate access to individual SKUs, often for piece picking.

Shuttle & Crane-Based AS/RS

The most common ASRS warehouse system utilizes either automated stacker cranes (moving vertically and horizontally) or advanced, high-speed shuttles for automatic pallet retrieval system. Shuttles offer modularity, while cranes offer the greatest height capability.

High-Rise AS/RS Systems

Refers to systems built above 40 feet, utilizing the specialized ASRS crane system to maximize use of the vertical cube. These facilities are often purpose-built around the high bay automated storage system structure.

AS/RS Technical Specifications

Our systems are engineered for peak performance, ensuring they meet your throughput and capacity requirements.

System Performance Data

Throughput rates are measured by the number of cycles (double or single) per hour, with specialized designs offering high speed robotic retrieval capabilities.

System Capacity Info

Capacity is measured not just in pallet positions, but in the total usable cube, often resulting in millions of cubic feet of automated warehouse storage.

Operating Parameters

The system is designed to operate within strict tolerances for temperature, load weight, and pallet size, ensuring smooth 24/7 reliability.

AS/RS Applications

AS/RS is the ideal solution for:

- Buffer Storage: Holding inventory between production and distribution.

- Order Fulfillment: Providing Goods-to-Person picking for e-commerce and retail.

- Cold Storage: Automating operations in deep freeze or refrigerated environments where manual labor is difficult.

- Work-in-Progress (WIP): Managing intermediate product storage in manufacturing.

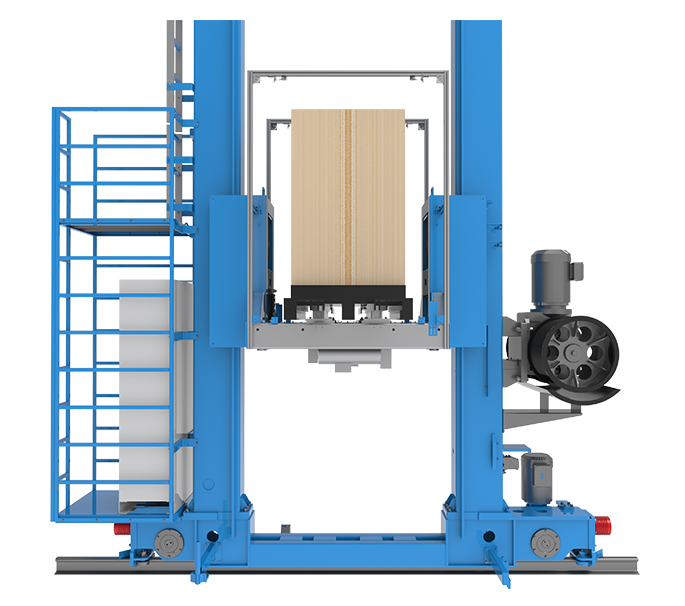

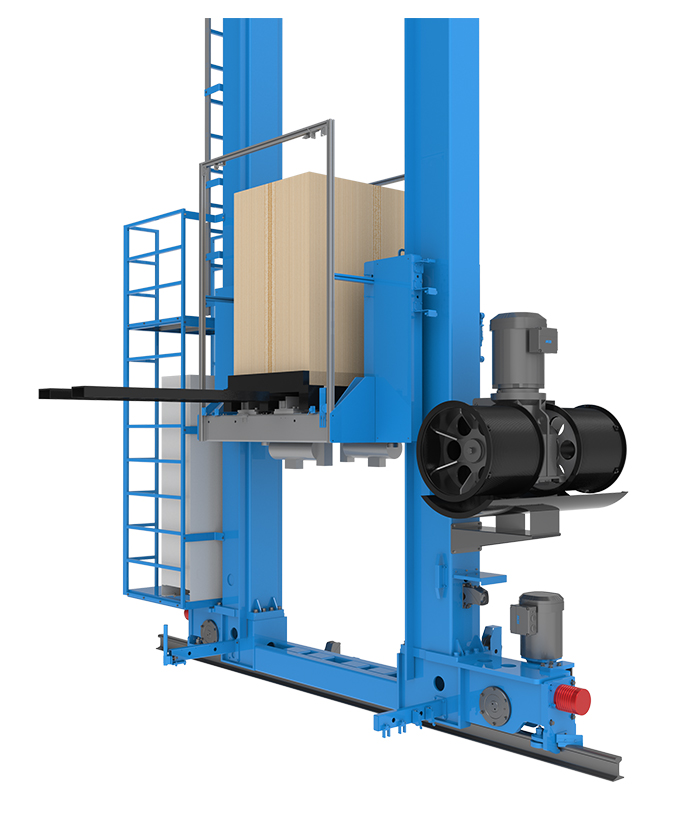

Sky/Ground Rail

The Eoslift stacker adopts sky rail and ground rail systems, and all the rails in the system are produced by Eoslift certified suppliers in same batch. The quality of the supplier's products enjoys excellent reputation in the industry, ensuring that the system has sustained high performance measurers.

Pallet stacker

Pallet stackers are much more efficient than forklift vehicles. Efficient stackers can meet your access needs in roadways. Eoslift stacker can be widely used for different unit loading range and warehouse height.

In-out Warehouse Station

All series of pallet conveyors and AGV produced by Eoslift are committed to meeting the needs of different customers. Therefore, there many options of in-out warehouse stations for selection from the cost-effective fixed workstation to the full-automatic solution, which can seamlessly connect the production area, the conveying area, the sorting area, the storage area and the receiving area. Our goal is to improve the working efficiency of customers and save their time.

Goods Shelves

Eoslift shelves are subject to high-demand quality inspection and certification to ensure that the shelf system meets national standards. Eoslift is fully responsible for seamless integration of shelves and equipment to ensure uninterrupted and efficient work.

Control and Software System

Eoslift stacker adopts control and software system independently developed by themselves. Intelligent location control software is connected with warehouse management system or enterprise resource planning system (ERP) to ensure the safety, control, and management of production. Users can view the order status and the provided service diagnostic information on the system.

| Rich Industry Experience | |

| Efficient and Professional After-sales Service | |

| Excellent Product Performance | |

| Special Design According to Customer's Special Working Environment | |

| Compliance with Europe's Highest Security Level | |

| Low Energy Consumption and Energy Recycling Technology |

| Conventional Stacker ES | |

|---|---|

| Maximum Load Capacity | 1102.3-3306.9 lb |

| Maximum Height | 275.6-984.3 in |

| Travel Speed | 7086.6 in/min |

| Travel Acceleration | 13.8 in/s2 |

| Hoisting Speed | 2362.2 in/min |

| Hoisting Acceleration | 19.7 in/s2 |

| Fork Speed | 31181.1/2362.2 in/min |

|

|

| Light Stacker EM | |

|---|---|

| Maximum Load Capacity | 44.1-440.9 lb |

| Maximum Height | 118.1-315 in |

| Travel Speed | 8661.4 in/min |

| Travel Acceleration | 31.5 in/s2 |

| Hoisting Speed | 2362.2 in/min |

| Hoisting Acceleration | 019.7 in/s2 |

| Fork Speed | 31181.1/2362.2 in/min |

|

|

| Overweight/Ultra High Stacker EH | |

|---|---|

| Maximum Load Capacity | 44.1-440.9 lb |

| Maximum Height | 118.1-315 in |

| Travel Speed | 8661.4 in/min |

| Travel Acceleration | 31.5 in/s2 |

| Hoisting Speed | 2362.2 in/min |

| Hoisting Acceleration | 019.7 in/s2 |

| Fork Speed | 31181.1/2362.2 in/min |

|

|

| Transfer StackerEP | |

|---|---|

| Maximum Load Capacity | 1102.3-17637 lb |

| Maximum Height | 275.56-984.3 in |

| Travel Speed | 4724.4 in/min |

| Travel Acceleration | 13.8 in/s2 |

| Hoisting Speed | 1181.1 in/min |

| Hoisting Acceleration | 19.7 in/s2 |

| Fork Speed | 1181.1/2362.2 in/min |

|

|