What Are AGVs?

Automated Guided Vehicles (AGVs) are mobile robots that follow markers, wires, or vision systems to transport loads automatically around a facility. Unlike Autonomous Mobile Robots (AMRs), AGV transport system navigation is highly structured and repeatable. This makes them ideal for fixed routes with predictable loads, such as moving product between production lines, receiving docks, and storage areas. AGVs are essential tools for large-scale, 24/7 operations seeking significant labor reductions and improved safety standards.

AGV Features & Advantages

Our AGV warehouse automation solutions are built with advanced technology to deliver superior performance and return on investment:

- Reliable Navigation: Utilizes cutting-edge AGV navigation systems, including laser guided AGVs (L-GVs) and magnetic track AGVs, ensuring precise, repeatable positioning.

- Safety Integration: Equipped with smart sensors and safety bumpers to stop instantly upon encountering an obstruction, ensuring are AGVs safe in warehouses and protecting personnel.

- Automated Pallet Transport: Specifically designed for handling standardized unit loads, providing automated pallet transport throughout the facility.

- Reduced Labor Costs: Handles dull, dirty, and dangerous repetitive tasks, allowing personnel to focus on high-value operations.

- AGV Fleet Control System: Centralized software manages traffic flow, battery charging, and task allocation for maximum utilization and efficiency.

- Scalability: Easily add more autonomous warehouse vehicles to the system as your throughput demands increase.

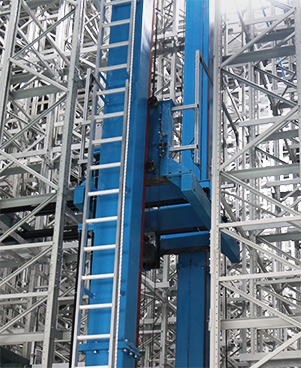

High safety

The stacker is designed according to the highest safety level in Europe

High hardware configuration

Key components and controllers are European high-end brands

High control performance and rich functions

1. Operate the stacker with multiple positions and time sharing 2. Applicable to storage requirements of complex cargo boxes 3. High-speed and smooth operation curve

Hoist the wire rope 6 times safety factor design, the choice of imported lubrication free wire rope

Catcher Abnormal and overspeed lifting can effectively put the pallet tongs on the guide rail of the upright column

Cases and Application

AGVs are versatile systems integrated across various logistical functions. Here are the common applications:

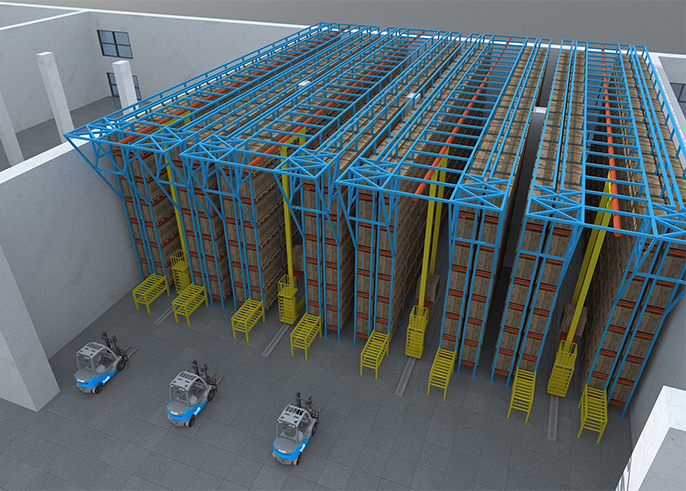

Automated Steroscopic Warehouse

AGVs can deliver and retrieve pallets directly to the infeed/outfeed lanes of high-bay AS/RS systems, forming a completely hands-off storage and transport loop.

Shuttle-type Warehouse

Used to stage and retrieve items from the ground level of shuttle racking systems, connecting the dense storage block to the main conveyor lines.

Robotic Mini Load Storage Systems

AGVs transport totes or bins from the Mini-Load system's output to final staging or packing areas, linking automated storage directly to fulfillment.

Pallet Stacking Systems

Deploy AGVs to automatically move finished product from the robotic palletizer station to the dedicated racking or staging lanes, closing the loop on end-of-line automation.

AGV Models & Specs

We offer models tailored for different loads, from low-profile tuggers to counterbalance forklift-style pallet handling AGVs.