What Is a Robotic Mini-Load Storage System?

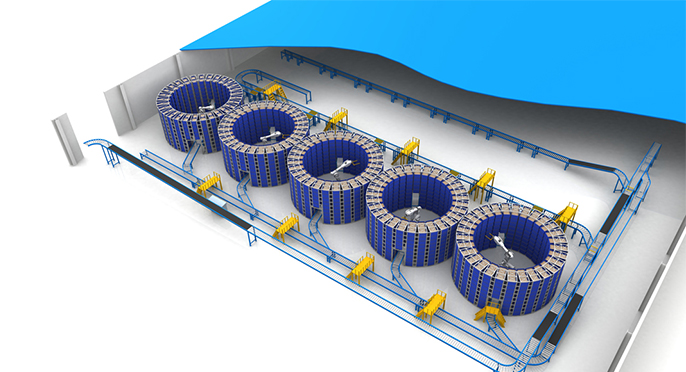

A robotic mini load storage system is a form of Automated Storage and Retrieval System (AS/RS) specialized for handling small inventory units (totes or cartons). It creates a box-type automated warehouse system where high-speed robotic extractors or shuttles travel horizontally and vertically within the structure to access inventory. This approach is fundamental to robotic picking and storage solutions, significantly reducing the time and labor associated with manual piece picking.

Key Features & Advantages

Our Mini-Load solutions are engineered for high-velocity, high-SKU operations, offering several distinct advantages:

Short Processing Time

By utilizing the direct Goods-to-Person principle and automated small-part handling, the time required to retrieve an item is reduced to seconds, significantly improving overall order fulfillment speed.

High Space Utilization

This system achieves high density robotic storage by building vertically and minimizing the aisle space needed for conventional lift equipment, making it an efficient use of your physical footprint.

Direct Access to Each Item

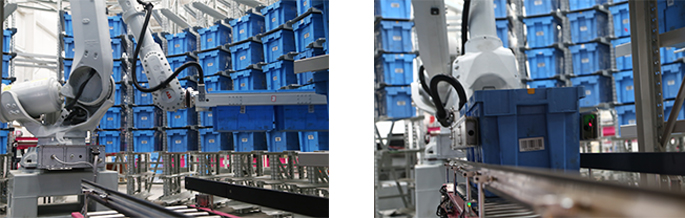

The automated small part retrieval system provides 100% access to every single tote or box without requiring human travel, streamlining inventory management and retrieval for accurate, on-demand picking.

How the Mini-Load System Works

The system integrates specialized racking with robotic mechanisms. Totes are stored deep and high. When a picking request is received, the central control software directs a robotic shuttle to retrieve the specific tote. The tote is then automatically transported via conveyor to the designated ergonomic picking station for the robotic warehouse picking system, and then returned to storage. This process ensures quick and efficient fulfillment.

Applications of Mini-Load Storage Systems

The robotic mini load storage system is a perfect fit for operations that deal with:

- E-commerce and Mail Order: Rapid fulfillment of high volumes of small, diverse items.

- Component Storage: Storing and retrieving electronic parts, spare components, or tools in manufacturing.

- Buffering: Holding work-in-progress (WIP) or kitting components for assembly lines.

- Retail Replenishment: Staging fast-moving small goods for store delivery.

System Options & Automation Integration

The Mini-Load system is part of a holistic automation ecosystem. We integrate it with other technologies to create a complete solution:

Automated Stereoscopic Warehouse

The Mini-Load system forms the internal storage core of the larger automated stereoscopic warehouse structure.

Shuttle-Type Warehouse

We link Mini-Load systems with high-density shuttle storage to cover all inventory sizes—from small parts (Mini-Load) to full pallets (Shuttle).

Picking Systems

The system serves as the feed for advanced robotic picking and storage solutions, optimizing the rate and accuracy of the final human or robotic interaction.

Pallet Stacking Systems

Connects the output of the Mini-Load system to automated palletizing zones, ensuring final product staging is seamless.

AGVs

AGV automated guided vehicle systems are used to transport incoming materials to the Mini-Load input stations or take completed orders away from the picking zones.

Short processing time

Box-type automatic warehouse can use containers, boxes or shelves to store widgets, which can save space and time and cost.

High utilization of space

Applicable:Mainly used for storage of many kinds of small parts with limited quantity in each category, and when warehouse production efficiency requirements are high.

Directly accessed to each piece of goods

A robotic arm is used to store, take and pick each piece of goods, which shortens the picking time of each piece of goods and achieves higher transshipment efficiency in the warehouse.

Applicable:Mainly used for storage of many kinds of small parts with limited quantity in each category, and when warehouse production efficiency requirements are high.

Cases and Application