What Is a Pallet Stacking System?

A pallet stacking system (often referred to as a robotic palletizing system or depalletizing system) uses robotic arms or specialized machinery to automatically arrange cases, bags, or items onto a pallet in a specific, stable pattern. These systems are critical components of a modern automated packaging warehouse system, eliminating the slow, repetitive, and injury-prone tasks of manual stacking, ensuring high-efficiency and safety at the end of the production line.

Key Features & Advantages

Our robotic palletizing solutions are engineered for precision and adaptability.

Multi-Spec Goods Handling

Utilizing advanced sensors and AI-driven pattern recognition, our systems are capable of mixed product palletizing, allowing the robotic palletizer stacking mixed-size goods onto a single pallet efficiently and stably.

High-Speed Processing Performance

Through features like multi-manipulator pallet stacking and dedicated software, our automated pallet stacking systems provide high-efficiency processing performance that dramatically outpaces manual stacking speeds.

Flexible Stacking for Custom Needs

Software control allows for quick pattern changes, ensuring flexible stacking for custom needs based on customer specifications, shipping requirements, or dynamic packaging lines through automated packaging line integration.

How Pallet Stacking Automation Works

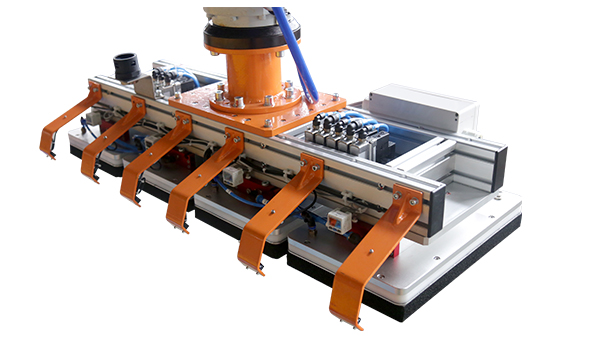

The core of warehouse pallet stacking automation involves product entering the system via conveyor. Vision systems identify the product size and type, and the control system selects the correct stacking pattern. The robotic pallet stacking arm, equipped with a specialized gripper, picks up the product and places it on the pallet with perfect precision. This continuous, optimized cycle achieves significant pallet stacking efficiency improvements.

Applications of Pallet Stacking Systems

Automated pallet stacking is essential across a variety of industrial settings.

- Food and Beverage: High-speed stacking of cartons, cases, and flexible packaging.

- Consumer Goods: Palletizing finished boxes before warehousing or shipping.

- Manufacturing: Stacking components or raw materials onto pallets for internal transport.

- Pharmaceuticals: Accurate, gentle handling of sensitive packaged products.

Pallet Stacking System Options

We integrate pallet stacking systems with other automation technologies for a cohesive operation.

Automated Stereoscopic Warehouse

Pallets stacked by the robotic system are immediately fed into the high-bay storage structure.

Shuttle-type Warehouse

The final pallet is automatically delivered to the input/output lane of the shuttle system for high-density storage.

Robotic Mini-Load Storage System

Products retrieved from the Mini-Load system can be consolidated and fed to the robotic palletizer for final stacking.

Picking System

Pallet stacking systems can serve as depalletizers to break down bulk pallets into individual layers for automated picking system interfaces.

AGV Guided Vehicles

AGV Guided Vehicles are used to shuttle empty pallets to the robotic stacker and remove finished, full pallets to the staging area.

AS/RS Integration

The system acts as the gateway, feeding completed pallets directly into the AS/RS Integration crane system.

It can handle multi-spec goods

Based on the powerful artificial intelligent algorithm and vision system, it can handle various SKUs flexibly, including small boxes, small cans, wide-mouth bottles on cardboard pallets, open and sealed cartons and various beverage packaging cans.

Superior Business Processing Performance

In this system, the stacker can achieve excellent throughput. It can operate continuously when the pallets are exchanged without stopping. The stacking efficiency is higher than any other automatic stacker or manual stacking mode.

Flexible in order to meet customer needs

Eoslift mixed stacking software can set pallet stacking mode according to customer's needs, determine stacking sequence according to enterprise data (such as size, weight, packaging quality and other attributes), optimize pallet stacking density, and then reduce transportation costs.